Listen to “AD #3176 – Nissan To Make Old Parts Without Dies; Honda Invents New Airbag; EVs Could Cost People Their Jobs” on Spreaker.

Follow us on social media:

Runtime: 7:40

0:07 IIHS Finds Big Improvement in Car-To-SUV Crashes

1:14 Nissan To Make Old Parts Without Dies

3:21 EVs Could Cost People Their Jobs

4:24 OEMs Unlikely to Make EV Motors In-House

5:36 Honda Invents New Airbag

6:33 Audi Develops Digital OLEDs

Visit our sponsors to thank them for their support of Autoline Daily: Bridgestone, Intrepid Control Systems, and Schaeffler.

This is Autoline Daily, reporting on all aspects of the global automotive industry.

IIHS FINDS BIG IMPROVEMENT IN CAR-TO-SUV CRASHES

A few decades ago, a crash with an SUV and a passenger car would likely be fatal for the people in the car. But a new study from the Insurance Institute of Highway Safety found that the safety disparity is starting to decline. From 2013 to 2016, the fatality rate for car-to-SUV crashes with SUVs that were up to four years old was 28% higher than the rate for car-to-car crashes. But that’s down from a rate of 132% from 1989 to 1992. Researchers attribute the improvement to stronger structures and side airbags in cars as well as lower front ends on SUVs. While SUVs have made big strides, it’s a different story for pickups. Drivers in cars and minivans are two and a half times more likely to die in an accident with a pickup than with another car or minivan. Researchers attribute that to the big weight differences in those types of vehicles.

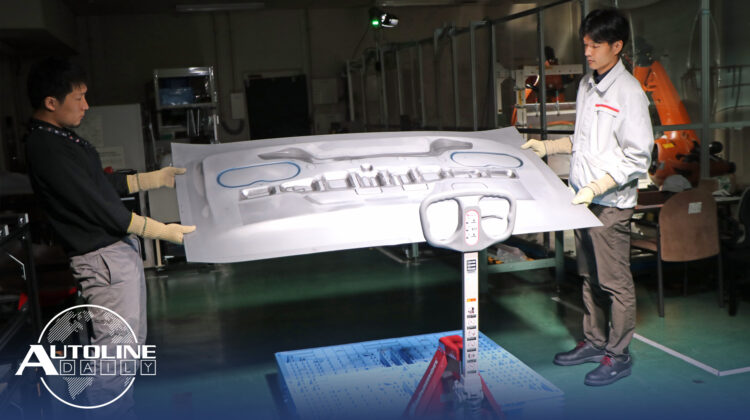

NISSAN TO MAKE OLD PARTS WITHOUT DIES

Nissan developed a new manufacturing technique that could make parts for discontinued models more widely available. Known as dual-sided die-less forming, it involves two robots working from opposite sides of a steel sheet, using diamond-coated tools to shape the steel. In the U.S., automakers are required to make sheet-metal service parts available for 10 years. But keeping old dies around for a decade can be pretty expensive. This new technique is more flexible, has shorter lead times and lower upfront costs, which could make it commercially viable to produce replacement parts for discontinued models for a long time to come.

And be sure to tune into Autoline After Hours this Thursday afternoon for some of the best insider discussions in the industry. That’s 3PM eastern time on our website, Autoline.tv.

Autoline supports the automotive industry….because it touches all aspects of transportation. Whether its trucks, trains, ships or planes, the auto industry keeps them on the road, on the rails, in the air or on the seven seas. It’s the economic engine of the economic engine. And that’s why we’re proud to say that Autoline is an advocate for the automotive industry.

EVs COULD COST PEOPLE THEIR JOBS

However, at some point in the future electric cars are going to catch on and that poses a risk for the tens of thousands of workers who manufacture traditional piston powertrains. A piston engine car uses over 100 forgings. An EV uses less than 10. A traditional car uses 150 pounds of aluminum castings. An EV uses 80. And of course, EVs don’t need radiators, exhaust systems, mufflers and a host of other components. Even if electric cars only reach 25% of all sales, that could eliminate 30,000 jobs just in the U.S. alone. And it’s not as if those jobs can transition to making EV batteries, because battery assembly is already 99% automated. We probably have about a decade before this really hits home and every country that makes cars better start making plans right now to figure out how they’re going to deal with this job displacement.

OEMs UNLIKELY TO MAKE EV MOTORS IN-HOUSE

And along the same lines, will car companies make their own electric motors for electric cars? Probably not. Powertrain executives tell us their customers cannot tell the difference from one electric motor to another. That means automakers can’t use electric motors to differentiate their brands from the competition. So why make them in-house? Besides, there are a number of Tier 1 suppliers who make electric motors, and they can sell them to all automakers. That means suppliers will have even greater manufacturing scale than any car company and will be able to make those engines at lower cost. We can’t cite our sources for this information because no one will talk about it publicly. They’re afraid of scaring all their employees who currently work on internal combustion engines.

HONDA INVENTS NEW AIRBAG

To help improve the safety of its vehicles, Honda R&D Americas developed a new airbag along with airbag supplier Autoliv. It’s designed to reduce the potential for injuries in a wider variety of frontal accidents, particularly front passengers in angled crashes. Unlike conventional airbag systems that have a single inflatable compartment, the new system utilizes four major components: three inflated compartments, a center chamber and two outward-projecting side chambers that create a wide base across the dash, along with a “sail panel” that stretches between the two side chambers at their outermost edge. Similar to a baseball catcher’s mitt, the sail panel catches and decelerates the occupant’s head while also engaging the side chambers, pulling them inward to cradle and protect the head, mitigating the potential for injury.

AUDI DEVELOPS DIGITAL OLEDs

Audi has been at the forefront of lighting technology and in 2016 introduced its first series produced OLED light in the rear taillight of the TT RS. It’s now expanding on that technology with the introduction of digital OLEDs, which are broken up into 50 different segments and each segment can have its brightness adjusted from the one right next to it. That means the same basic hardware could be used on a number of vehicles, but produce a different lighting design for each. Digital OLEDs could also be used to communicate with other road users, like providing a warning that there’s a dangerous situation ahead.

But that wraps up today’s report, thanks for watching.

Thanks to our partner for embedding Autoline Daily on its website: WardsAuto.com

Seamus and Sean McElroy cover the latest news in the automotive industry for Autoline Daily.