Follow us on social media:

Runtime: 10:29

0:17 Details on GM’s Ventilator Production

1:12 Ford Teams to Make Virus Equipment

2:10 FCA Will Make Face Masks

2:27 Tesla Ships Ventilators to California

2:41 How Bad Could Car Sales Get?

4:05 Organizations Band Together to Ask for Help

4:51 How Do We Fight This?

5:53 Aston Makes New 3.0L Turbo V6 In-House

6:32 NHTSA Clearing Path for AVs

7:12 H-D LiveWire Sets 24-Hour Distance Record

7:51 Predicting Malfunctions & Notifying Workers

Visit our sponsor to thank them for their support of Autoline Daily: Bridgestone.

This is Autoline Daily, the show dedicated to enthusiasts of the global automotive industry.

And we’ve got some good news to report. Detroit is rolling up its sleeves and getting heavily involved in the fights against the coronavirus.

DETAILS ON GM’S VENTILATOR PRODUCTION

We’ve got more details on GM’s plan to make ventilators and the response has been terrific. GM is partnering with medical equipment maker Ventec and internally the effort is called Project V. GM is converting part of its plant in Kokomo, Indiana to build the machines. Within 48 hours it sourced 95% of the parts and it’s working on getting the final 37 parts it needs. The target is to make 5,000 ventilators a month with a delivery target of April 6. General Motors will buy the machines and will handle all the logistics for making and distributing them.

FORD TEAMS TO MAKE VIRUS EQUIPMENT

Ford is working with 3M and GE to manufacture respirators and ventilators in mass production. Ford is helping GE redesign its respirator to come up with a simplified design, and is going to assemble over 100,000 plastic face shields a week with the first ones getting distributed this week. Here’s a detail we love. Ford is grabbing off-the-shelf parts like fans from the Ford F-150’s cooled seats for airflow, and portable tool battery packs to power these respirators for up to eight hours. Details are still being worked out but the respirators will probably be made in a Ford plant by UAW workers. And the company will be using 3D printers at its advanced manufacturing center to make parts for all this medical equipment.

FCA WILL MAKE FACE MASKS

FCA plans to make 1 million face masks a month and donate them to police, EMTs and firefighters, as well as workers in hospitals and health care clinics. across the U.S., Canada and Mexico. FCA also marshalled its manufacturing, supply chain and engineering expertise to start quickly making the masks. It’s also looking at making ventilators and CEO Mike Manley says they will have more to announce in the coming days.

TESLA SHIPS VENTILATORS TO CA

Meanwhile Tesla bought 1,255 ventilators in China and shipped them to California.

HOW BAD COULD CAR SALES GET?

So, how bad will it get for the auto industry this year? On a recent Autoline This Week, auto analyst Jeff Schuster from LMC Automotive shared his outlook for how bad car sales could look this year.

Jeff Schuster, LMC Automotive

“Just with what’s been announced, through a few minutes ago and what we’ve heard that hasn’t yet been announced. We’ve taken out more than 600,000 thousand units out of North American production just with the shutdown. I think the bigger issue is, while I agree that I think these are the different levels and stages, looking at supply chain, looking at production levels. I think demand is what ultimately is going to drive this and we’re looking at demand, you know that certainly is going to take a lot more than that. We’re just from a range, down probably sub-15 right now for the year, 15 million units for the U.S. I think looking at a North American market that’s probably off anywhere between 12 and 15 percent and I suspect it’s going to get worse. So I think the industry is going to have to put the seatbelt on and probably should go with a 5-point seatbelt, at least through the remainder of the year.”

For more of that discussion, you can watch it right now on our website, or on our YouTube channel.

ORGANIZATIONS BAND TOGETHER TO ASK FOR HELP

In what we think is a first, the Alliance for Automotive Innovation, the National Automobile Dealers Association and the Motor & Equipment Manufacturers Association have banded together to ask the White House and Congressional leaders for help during the coronavirus outbreak. The organizations are calling for a stimulus package that includes the creation of credit facilities, tax deductibility on paid leave at companies with more than 500 employees, delayed or deferred quarterly tax payments, expanded expensing for machinery and equipment and delaying the implementation of the USMCA. Analysts are predicting auto sales could fall as much as 40% in March, which would not only hurt the industry but the American economy at large.

HOW DO WE FIGHT THIS?

And this brings us to the question of the day. How do we balance the need to fight the coronavirus with the need to keep the economy running? Do we stop everything and risk plunging the world into another Great Depression? Or do we figure out some way to manage the risk and try to get the economy back on its feet before the year is over? We’d love to hear your thoughts. And please, leave out the political finger pointing. There’s plenty of that going on everywhere else. What we’re interested in is getting good ideas on how to solve this crisis, not figure out who to blame. There will be plenty of time for that later.

ASTON MAKES 1ST IN-HOUSE ENGINE IN OVER 70-YEARS

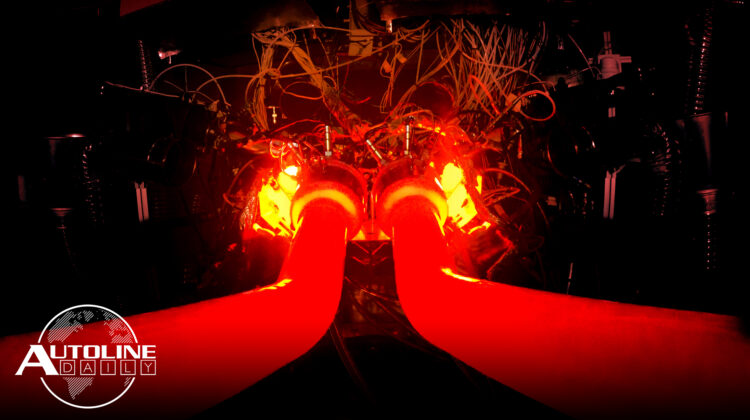

When so many automakers are developing electric cars, Aston Martin is going in the opposite direction. The automaker released information about its first engine built in-house since 1968. It’s a turbocharged 3.0L V6 that was designed to be electrified from Day One and will be used in the Valhalla sports car. Aston calls Valhalla the ‘Son of Valkyrie.’ Valkyrie is the company’s top supercar and the Valhalla will slot below it. Even so, when the new V6 is paired with electrification it will become the most powerful setup in Aston’s range. It will be mounted mid-ship in the Valhalla, which goes on sale in 2022.

NHTSA CLEARING PATH FOR AVs

If you ask anyone about what’s holding back autonomous vehicles, one of the first things they will bring up is rules and regulations. NHTSA took a historic step to removing some of those barriers. It issued a proposal to make federal safety standards more modern and clear up confusion in occupant protection. That includes removing rules for manual controls in autonomous vehicles and safety standards for vehicles that will never have any passengers, like those used for delivery. Now NHTSA needs your feedback. It’s looking for comments from the public on every aspect of this proposal.

H-D LIVEWIRE SETS 24-HOUR DISTANCE RECORD

Many people made fun of the Harley-Davidson Livewire’s 100 miles of range. But we all know there are hyper-milers that can smash any range estimate and a Swiss rider set an unofficial 24-hour distance record on an electric motorcycle. The rider went a little under 1,100 miles in just under 24-hours, which is over 200 miles more than the last record set in 2018. And they did it on their own! That sounds like a lonely trip.

PREDICTING MALFUNCTIONS & NOTIFYING WORKERS

Today’s cars are becoming more complex and so are the factories that build them. But many factory floor workers don’t have a formal education in statistics or data mining. On last week’s Autoline After Hours our special guest was Jeff Trumble, whose company has developed AI software to help those workers. In the following clip he sheds more insight into the software.

Jeff Trumble, Trumble Inc.

“So, what we did is created a product that protected our target user community. All of that bright human capital on the factory floor. And what we did is protect them from having to do any statistics, any data mining skills. So, the product doesn’t require that from its user community. All of the monitoring, all of the statistics, all of the data mining is all done automatically. It’s an artificial intelligence piece of software. It understands where people work, what operations they’re responsible for, what shifts they work, it knows what products are running down the line. It knows what the specifications are, in terms of both the equipment, cycle times for example and it also knows design specifications. With all of that knowledge baked into the product, as it scans the factory floor around the clock 24-7. It looks for non-conformances, it ignores if everything’s fine. So, it’s like finding a needle in the haystack. If everything is fine, no one hears from the system. If something is emerging as a threat, and that’s the key, as it’s emerging, the system notifies the person closest to that particular operation or station that a correction needs to be made. And when you put all of these ingredients together what you have is proactive control of your factory floor, not reactive. And there are many good strategies out there but they’re still reactive and it has been for 100 years.”

You can watch that whole show right now on our website, or on our YouTube channel.

But that wraps up today’s show, thanks for watching and please join us again tomorrow.

Thanks to our partner for embedding Autoline Daily on its website: WardsAuto.com

John McElroy is an influential thought leader in the automotive industry. He is a journalist, lecturer, commentator and entrepreneur. He created “Autoline Daily,” the first industry webcast of industry news and analysis.